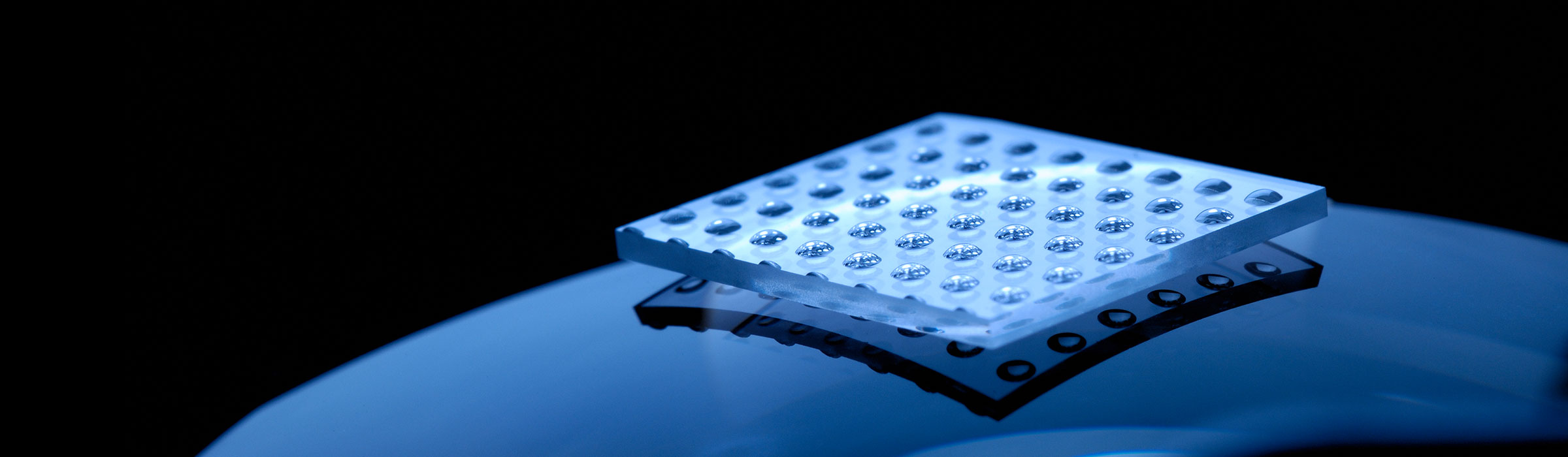

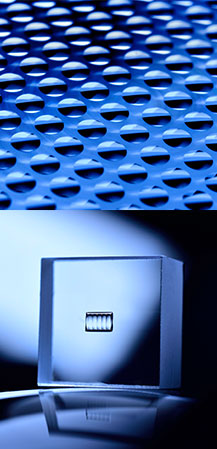

Microlens arrays with superior form accuracy are used for applications, where reliability and highest efficiency are crucial criteria. They range from beam transformation for fiber coupling over the homogenization of laser light up to the efficient combination of laser stacks of identical wavelength. The lateral dimensions of the arrays range from some millimeters in the micro-scale up to 45 millimeters for the macro-scale. The dimension of the array structures are typically in the submillimeter range.

With its unique production technique, INGENERIC is able to keep the form accuracy of the arrays within the submicron range. Customized microlens arrays are INGENERIC’s daily business: From lens design, prototype manufacturing and small series production to mass production.

- Advantages

- superior beam shaping

- efficient transformation and homogenization

- monolithic structure

- highest transmission due to minimized transition zones

- typical facet of 400um

- long term stability

Quality

We operate a strict quality control policy. For diagnosing the relevant product characteristics and thus ensuring the specified quality, INGENERIC has a considerable equipment of measurement devices available. Beyond that, certain products can further be tested in the application which they will encounter at your site.

In conjunction with our sophisticated manufacturing technology, this guarantees the production of optics with unsurpassed collimation and homogenization characteristics.