INGENERIC Micro-lens arrays used for finding new planets around the nearest stars

January 6, 2017. The University of Chicago develops a micro-lens array based pupil slicer and double scrambler for a new fiber-fed, red-optical, high-precision radial-velocity spectrograph to detect new planets around the nearest stars in the solar neighborhood.

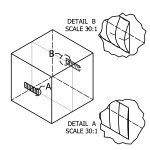

Image 1: Zemax image simulation (top) and actually measured output (bottom) of the pupil slicer. A round image of the telescope pupil incident on the front face of the first MLA is cut into 3 separate image parts and is refocused by the back facing MLA onto a single focal plane.

In order to achieve the desired resolving power of their instrument, scientists at the University of Chicago decided to use a pupil slicer. That approach is less critical in terms of mechanical stability compared to the more conventional image slicing technology but requires state-of-the-art micro optics. A 3x pupil slicer – producing three separate image sections of the telescope pupil on a single focal plane – was chosen to fulfill the resolving and throughput specifications of the instrument (Image1).

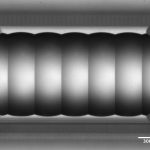

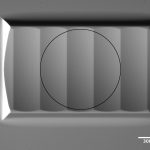

Micro-lens arrays form the basis for this pupil slicer. Different micro-lens types can be used to achieve this: With a cylindrical lens array the principle function was demonstrated in a conceptual design study. To achieve a better performance and fewer losses an adapted double-sided micro-lens array was needed (Image2). The base is a 5×1 lens array with a rectangular aperture (0.3×0.9 mm²) of the single lenses. The entrance surface has a spherical (Image3) and the exit surface has an aspherical shape (Image4) to compensate for aberrations and reduce the SAG of the lenses. An additional requirement is a high fill factor.

Image 4: Microscope image of the back facing MLA in diffuse illumination. This MLA has aspheric lenses with short radii of curvature.

Image 3: Microscope image of the front facing MLA in diffuse illumination with the size of the incident light beam shown as a circle.

The technology used by INGENERIC has the capability to achieve the specifications needed for that MLA. A fill factor of >98 % in combination with a form accuracy in the range of 50nm enables a high overall efficiency of the system.

INGENERIC micro-lens arrays in general offer several advantages such as high numerical apertures, highest transmission, high fill factor due to minimized transition zones, minimum aberrations due to high form accuracy. Double sided lens arrays can be realized and convince high center thickness accuracy and a precise orientation of the two sides. Thanks to the superior production technology INGENERIC can serve a variety of the customers’ requirements:

Detailed information on INGENERIC MLAs and customized solutions can be found here.

Click here to read the report of the University of Chicago in full length.