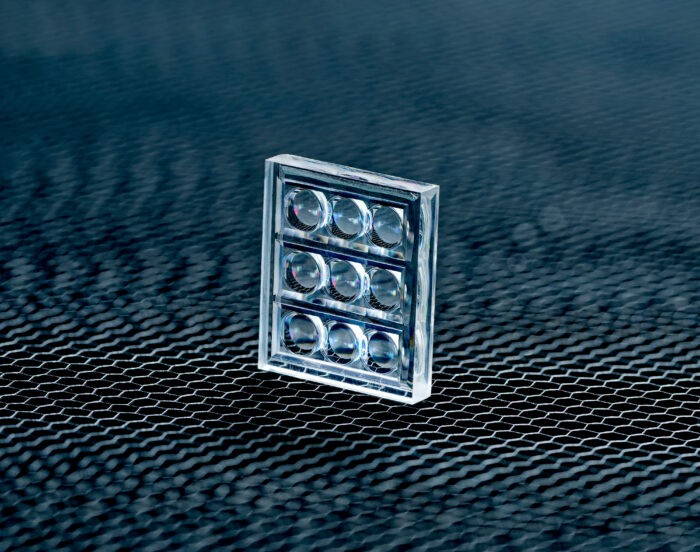

Product Innovation: Multichannel Microlens Array for Multispectral Imaging

INGENERIC Introduces New Meniscus Lenses as Q-Type Aspheres:

Q-Men 9 MLA with Varying Radii Sets Standards in Efficiency and Image Quality.

INGENERIC will showcase its latest development for multispectral imaging at SPIE Photonics West 2026: a 3×3 Multichannel Microlens Array (MLA) featuring meniscus lenses designed as Q-Type aspheres with varying radii. These highly functional optical elements are specifically tailored to meet the demands of modern multispectral camera systems, delivering exceptional precision in a compact form factor. The development of this product was carried out in collaboration with the Fraunhofer Institute for Applied Optics and Precision Engineering, which was responsible for the product design.

Multispectral camera systems enable simultaneous capture of images across various spectral ranges, from visible light to infrared and ultraviolet. This capability allows for the acquisition of spectral and spatial information with high resolution—an essential advantage in industrial quality control, environmental and agricultural monitoring, and biomedical diagnostics.

The newly developed micro lens array from INGENERIC consists of 3 x 3 lenses per array, with an overall dimension of 13.0 x 11.0 x 2.07 mm. The complex aspheric meniscus geometry combines both convex and concave surfaces. With varying radii, each lens is optimized for specific wavelengths, resulting in exceptionally high light yield and excellent image quality. A specialized anti-reflective coating (AR) reduces reflections to below 1% of the incident light, further enhancing imaging efficiency.

A standout feature of the array is its uniform light distribution across the sensor elements. This significantly improves contrast and image sharpness, which is crucial for precise applications such as vegetation analysis, yield forecasting, water quality monitoring, and climate research.

For production, the high-index glass K-VC89 is utilized, known for its low thermal expansion coefficient and high temperature stability. These properties provide ideal conditions for isothermal precision glass molding, the technology used by INGENERIC to manufacture the arrays. This process enables the reproduction of complex optical shapes with a form accuracy of less than 1 µm and a surface roughness of less than 2–3 nm Rq. Compared to conventional methods such as grinding or etching, isothermal precision glass molding offers higher precision, reproducibility, and scalability – providing significant advantages for demanding applications in research and industry.

“With this micro lens array, we are setting new standards in multispectral imaging. Our technology combines the highest optical quality with efficient manufacturing, opening up new possibilities for compact, high-performance camera systems,” says Dr. Stefan Hambücker, Managing Director of INGENERIC.